SPO1265 Rebirth

Winter 2012/13

1265 started life in 2002 with my own install of a Ford Crate 514. Transformations it has taken in 10 years are many,. I have broken just about every part between the gas pedal and the street, testing it to the max. Literally! I even did break the gas pedal! But probably it's most significant transformation was the 2012 winter project.... This transformation included Kaase P-51 heads and a pretty radical solid roller cam ground to Kaase Racing specs. When I started this project I talked to Jon Kaase because I wanted the advantage of his vast experience in pulling the most out of a BB Ford.. I was starting with an A460/4 bolt block, bored and stroked to 598ci./11:1cr . I asked Jon what he thought I should use for a cam. He asked all the regular questions. What kind of car? How would it be used etc. and then asked how much horse power was I looking for. I told him I wanted it very street-able, but given 598ci's I thought 800hp should be achievable... His reply was "absolutely!" WOW... Will that bring a smile to your face :-)...

Lots of apprehension with this project. Can you really get 800 HP and still be street able? I mean, do I even consider a 1500rpm idle street able.

The first day I thought I may get it out on the street, just before Christmas, old man winter decided to dump white stuff big time here in Michigan.... But alas..... Old Man Winter has taken a little break here in snow country and I've now managed about 50 street miles on the 598 monster...

First impressions?? OH WOW!!! Of course in temps of 50f and lower, you will never get enough traction to test the limits of the 800hp, BUT! The sound, the slow speed drive-ability and the feeling of pressing on the go pedal? This is going to be fun!! Idle is currently set about 1100rpm's. It will actually idle lower but it just sounds too cool at 1100. To me, stepping on the gas is like turning up the transformer on your ole Lionel train. No lag, no stumble, no hesitation, it's just go-on-demand!

I think a FUN summer is a coming :-)

Below are some of this winters photos....

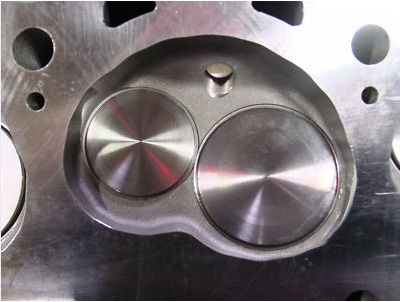

Left is a Cobra jet cast chamber that includes steam holes for the A460 block. Right is a P-51 with a machined chamber and no steam holes. I will be adding steam holes.

Pistons needed to be fly cut to accommodate the P-51 heads and a valve lift of up to .080". Kaase Racing provides this service.

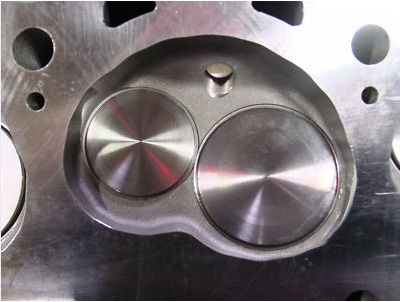

Note the steam hole between the cylinders. This is unique to an A460/Siamese block

P-51 heads installed

To make sure the new Firefly headers were a perfect match/no restriction,

I used my new P-51 heads to designed the header flange.

Test fit of the Firefly Performance header http://fireflyperformance.com/header460/

I switched to Tony Branda rocker covers because they provided better clearance to the relocated valve springs on the P-51 Heads.

The cam speced by Kaase Racing

Mechanical Roller Intake Exhaust

Duration @ .050" 272o 280o

Lift .743 .740

Back in the car and ready to rumble!!

Winter 2016/17

Since the last update, the car now has a stud girdle that required higher valve covers and FiTech EFI that required a new air cleaner

Learning about EFI is on going. I'm finding that it is very sensitive to proper battery voltage. It will not start when cold if the voltage drops below 10VDC while cranking. I believe I am running into this problem in part because the superformance Battery in mounted in the trunk and I get about 2.7VDC drop during cold cranking. Instead of tapping into the main starter cable for the ECU and Ignition, I now take power directly from the battery. That has helped, but because of the way the Superformance is wired, the ammeter is no longer accurate. More to come on this.

Winter 2017/18

From the beginning of this project, the valvetrain has been a challenge. Probably mostly due the extreme lift of the cam and high spring pressures. Now on my third set of lifters, third cam and second set of valve springs, I'm hoping this is sorted out for the long term.

The history:

Year one - The first failure was a broken rocker pedestal. This was probably more of a casting fault than anything else, but Kaase Racing agreed to fix the head at their cost and suggested I install a stud girdle. This was done.

Year 2 - The Crower Solid roller lifters that were new with this build, failed roller needle bearings and wiped out the cam. The advice form Kaase Racing was to switch to Jessel Over-sized (.937) lifters and back off a little on the cam opening ramp. It would be a major rebuild to strip it back to the bare block to bore the lifter bores, but that was what I did.

Year 3 – Two of the Jessel roller lifters failed wiping out another cam. This time I did a deeper dive into finding a way to make this engine live longer than one year. I backed off a little more on cam ramp, duration and lift. With the new cam, Comp recommended lower pressure springs. 483Lbs open down from 600lbs open. And finally a deep dive into lifters. I wound up switching to Crower EnduraMax bushing lifters. Check out what I found in my investigation below.

In addition, during this rebuild I found I had damage to the exhaust valve ends. My local engine builder is suspect of the valve quality. I had him replace all of the exhaust valves. I also now run lash caps, which I have found many racers do to help protect the valves.

I'm posting this after with only about 300 miles on this build. I will add updates as I have them.

Winter 2021/2022

After 4 years and 5000 miles, the 598ci has been pretty stable, but because of a recent valvetrain problem, this update will cover several topics

Valvetrain

Because of past valve train problems, I check lash often. During the 2021 summer I began to notice a steady increase in lash on #7 and #8 intake valves. Inspecting the Crane Gold rockers, I noticed a roughness in the roller roll. I suspect the needle bearings are failing, but of larger concern is how are the HIPPO Crower lifters doing? It was time to pull the intake for a complete inspection.

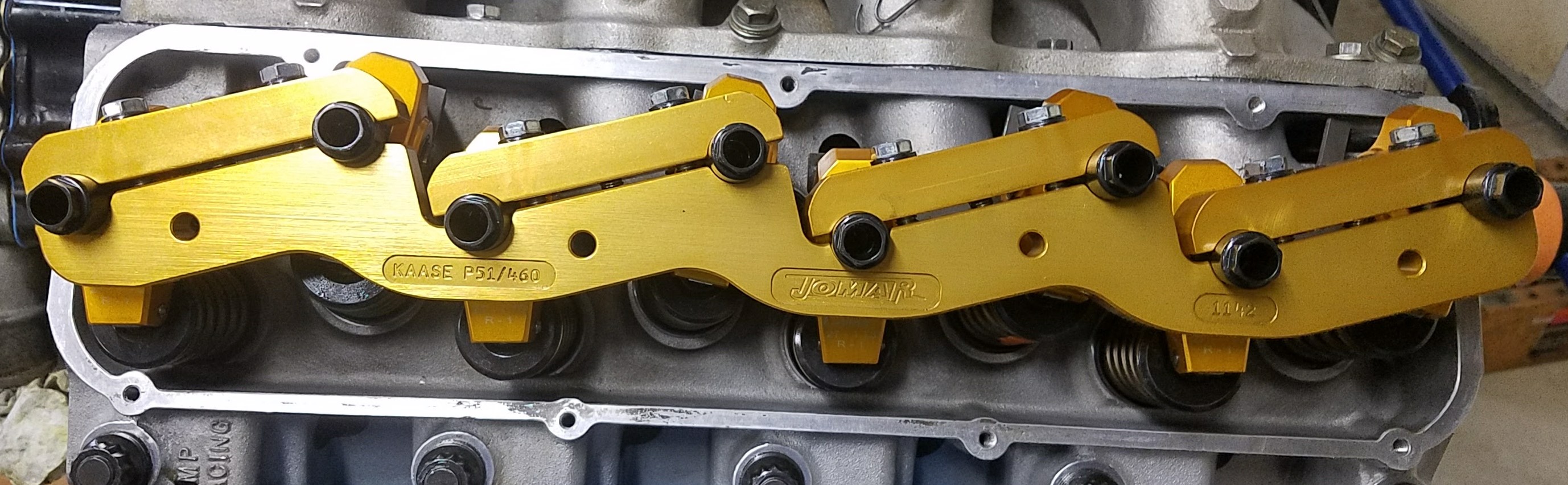

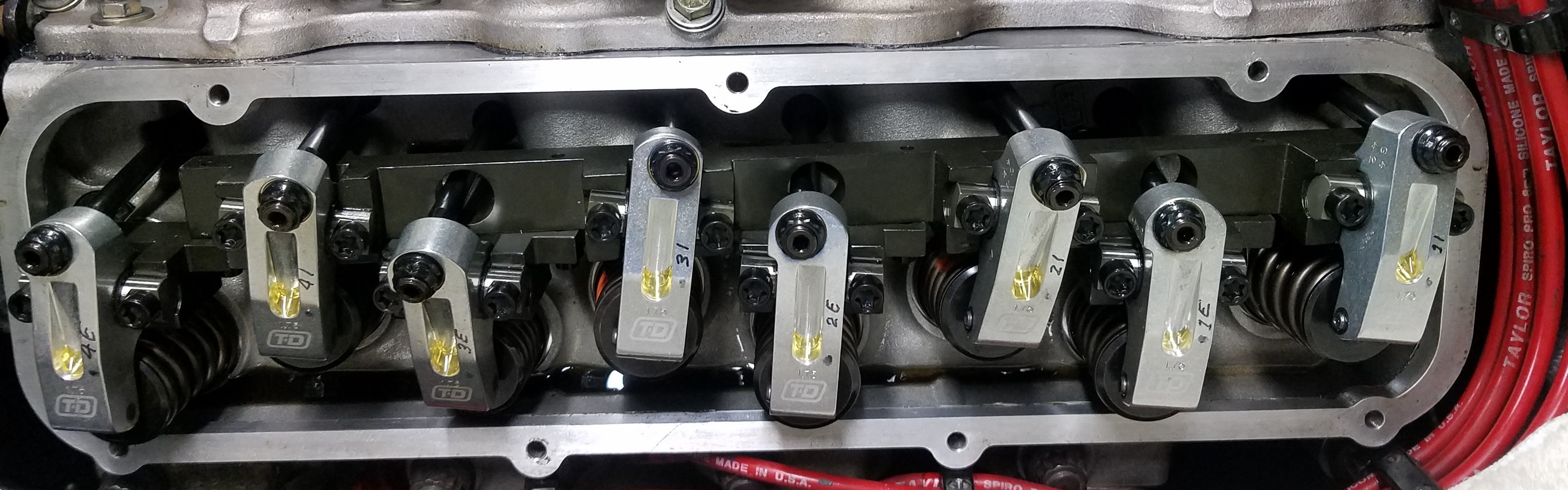

Close inspection of the HIPPO lifters relieved that they are as solid as the day they were installed. These lifters are now on my highly recommended list. So, back to the rockers. In total, I have failed 6 on this engine. I suspect the Crane Golds are just not cut out for heavy loads. Because JKRE now offers shaft mounted rockers from T&D which are said to be more stable, I am now going to make this upgrade.

Lash Caps

I started using lash caps because of damage that I was getting on valve stems. Probably from failing rocker rollers. This proved to be a good move because on this most recent inspection, I had two damaged lash caps. The caps saved the valve stems. However, I mentioned this to JKRE and they recommend not using lash caps with the W.W. rocker shaft. I will follow the recommendation and see how it goes.

Stud Girdle

This, naturally, will not be used with the rocker shafts which I consider to be a good thing. I have found the stud girdle to be very time consuming to install and can change lash by .001 if not installed perfectly. In general, stud girdles on canted valves are a pain.

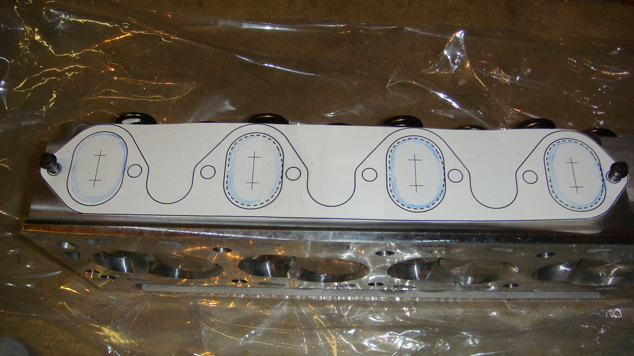

Previous stud rockers and stud girdle

New shaft rockers

EFI and oil consumption

Nothing new to report on the Fi-Tech as it has run flawlessly. It still requires 2 or 3 prime shots on cold start, but that is something I just do. I'm sure it can be tuned better for this, but just not a priority. What is interesting is that oil consumption is getting better. From 200-400 miles per quart to about 1000 miles per quart. What I most suspect is that carbureted, hot restarts were always a challenge with flooding, I suspect washing down the cylinders was preventing the rings from sealing. I have had no flooding issues with EFI. I have also changed from 20w50 oil to 10w40, but I am not sure that would make a difference in oil consumption.

Click here to go back to the projets page

Click here to go to Craig's Cobras